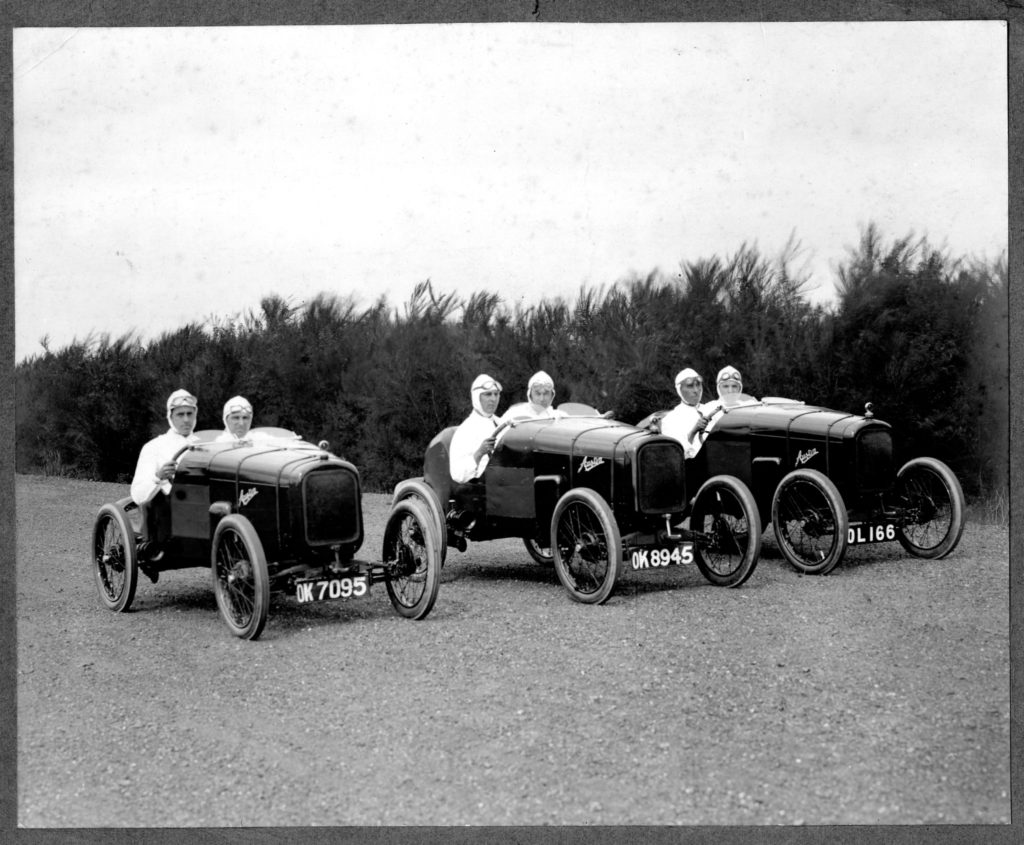

In 1923 Austin sent a team of three cars to contest the Voiturette Race in Boulogne, France.

The Austin Seven Boulogne was part of The Great Austin Seven Build Off with fellow Austin Seven inspired cars: the BMW 35/15 PS-DA3 Wartburg, the Rosengart LR2 and Bruce McLaren’s Austin Seven racer.

I have a lot of these profiles to personally compile having built ten cars either alone or as a team member so, to keep things interesting, I will try to find a different emphasis for each story. The Austin story is very much about building, re-building and learning.

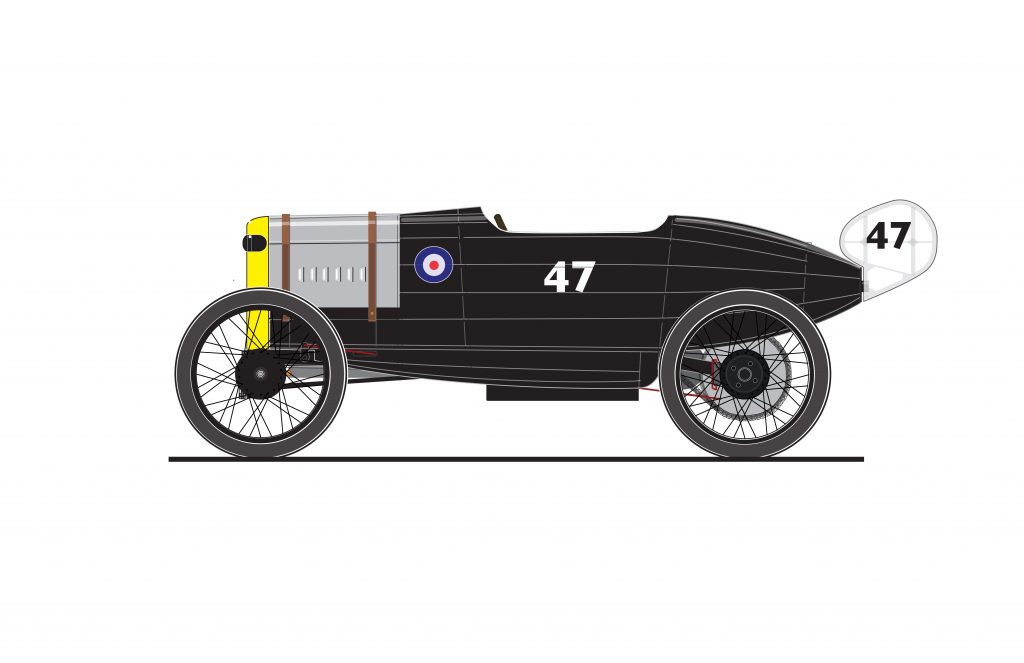

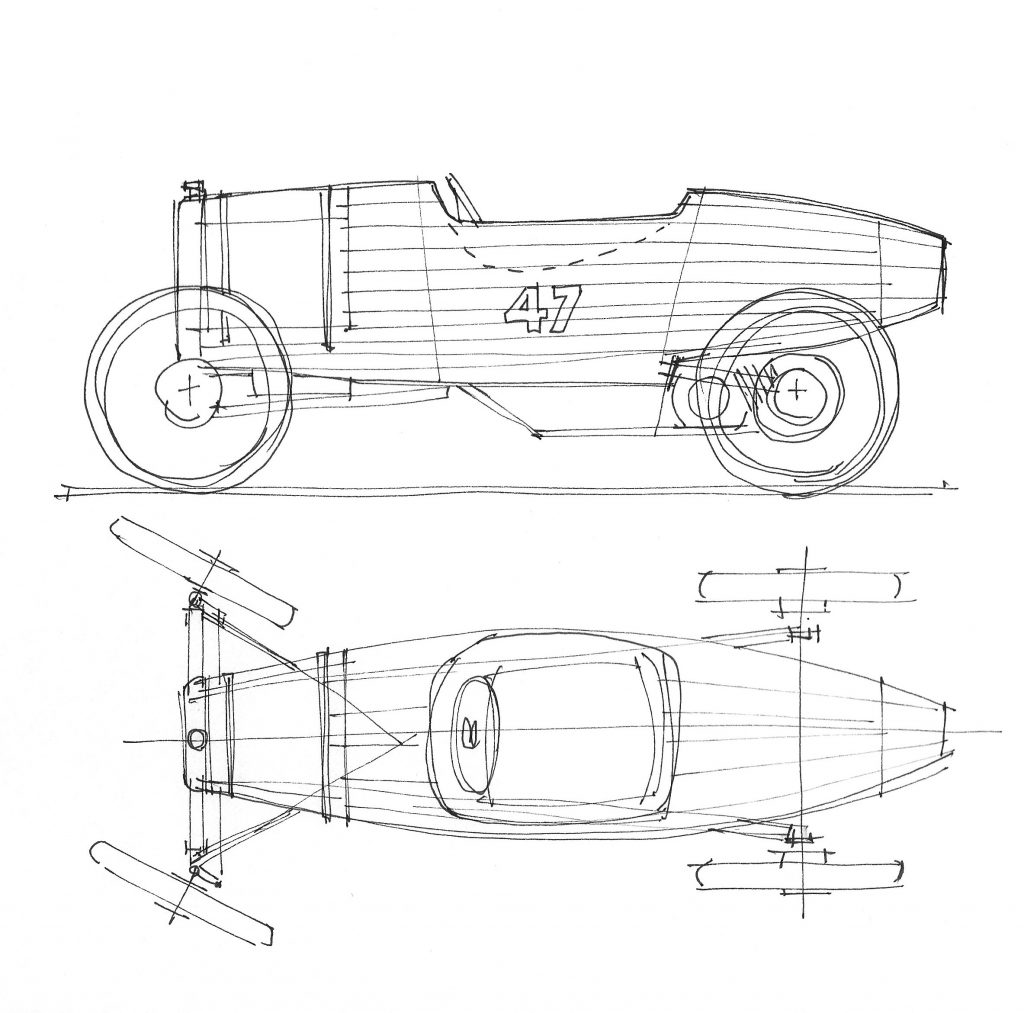

My primary inspiration image is below. – inspiration as much for the attitude and casual state of the car as for gleaning precise details. To be true to the original spirit, the car needed to be light, spindly and appear tall. This was not to be a heavily modified later-day Austin Seven Special, this was to be a genuine Austin Seven.

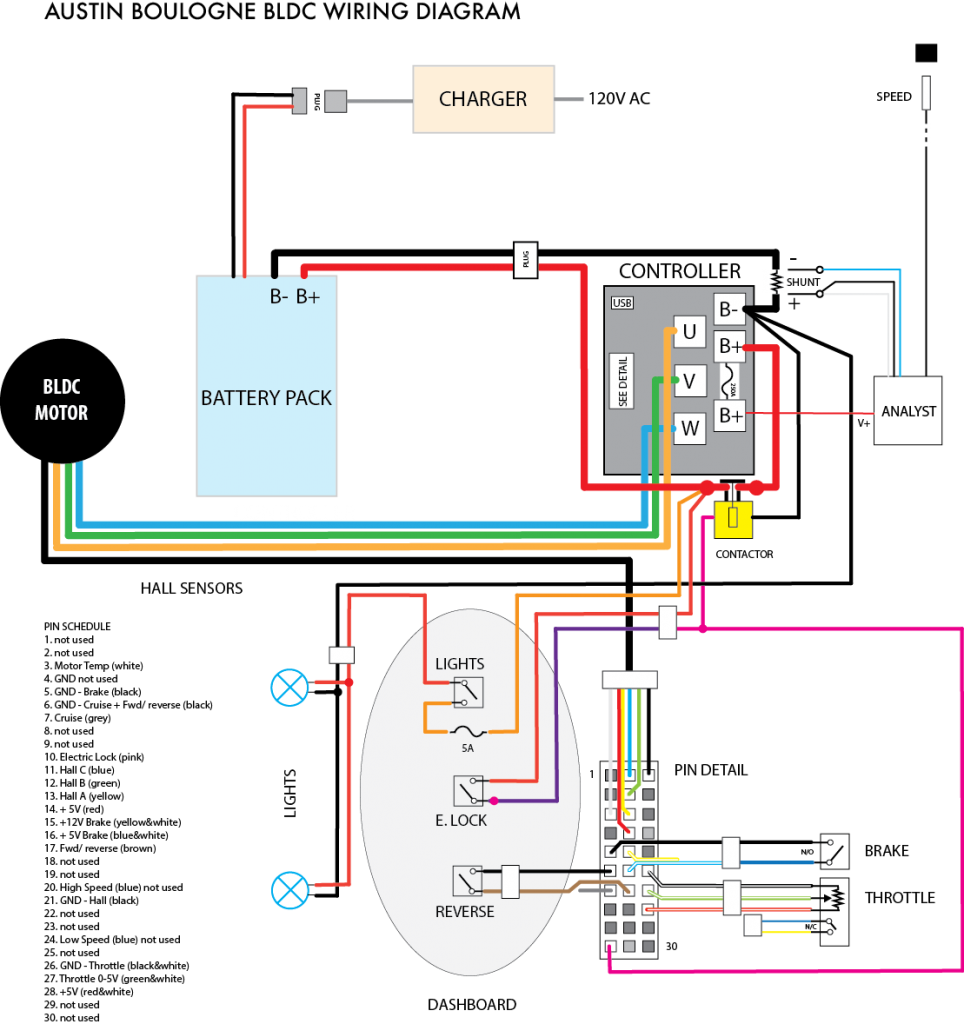

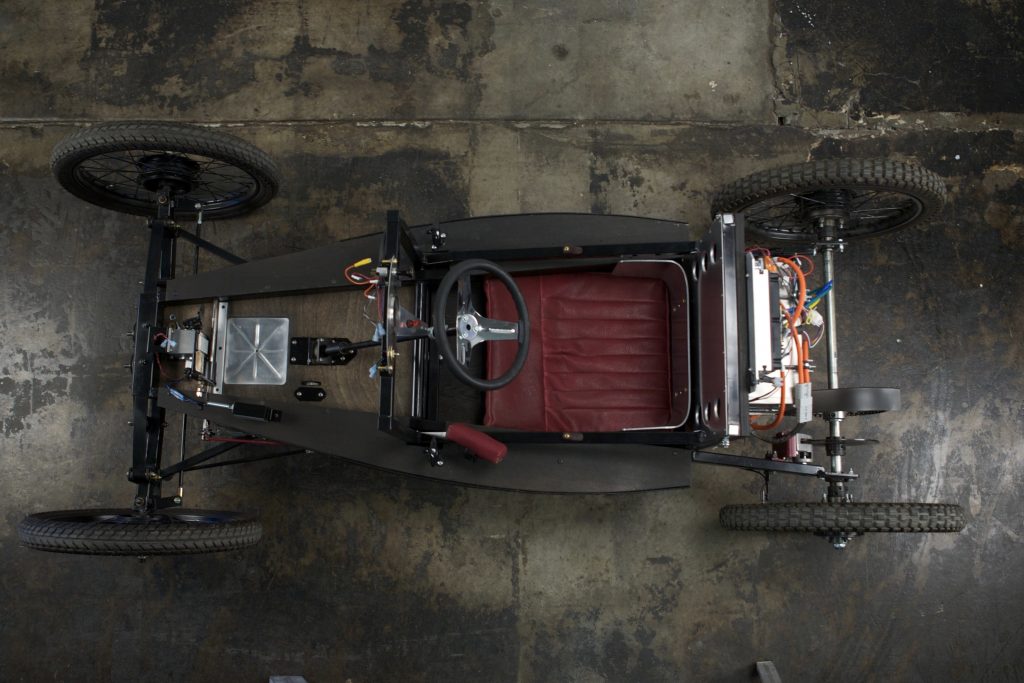

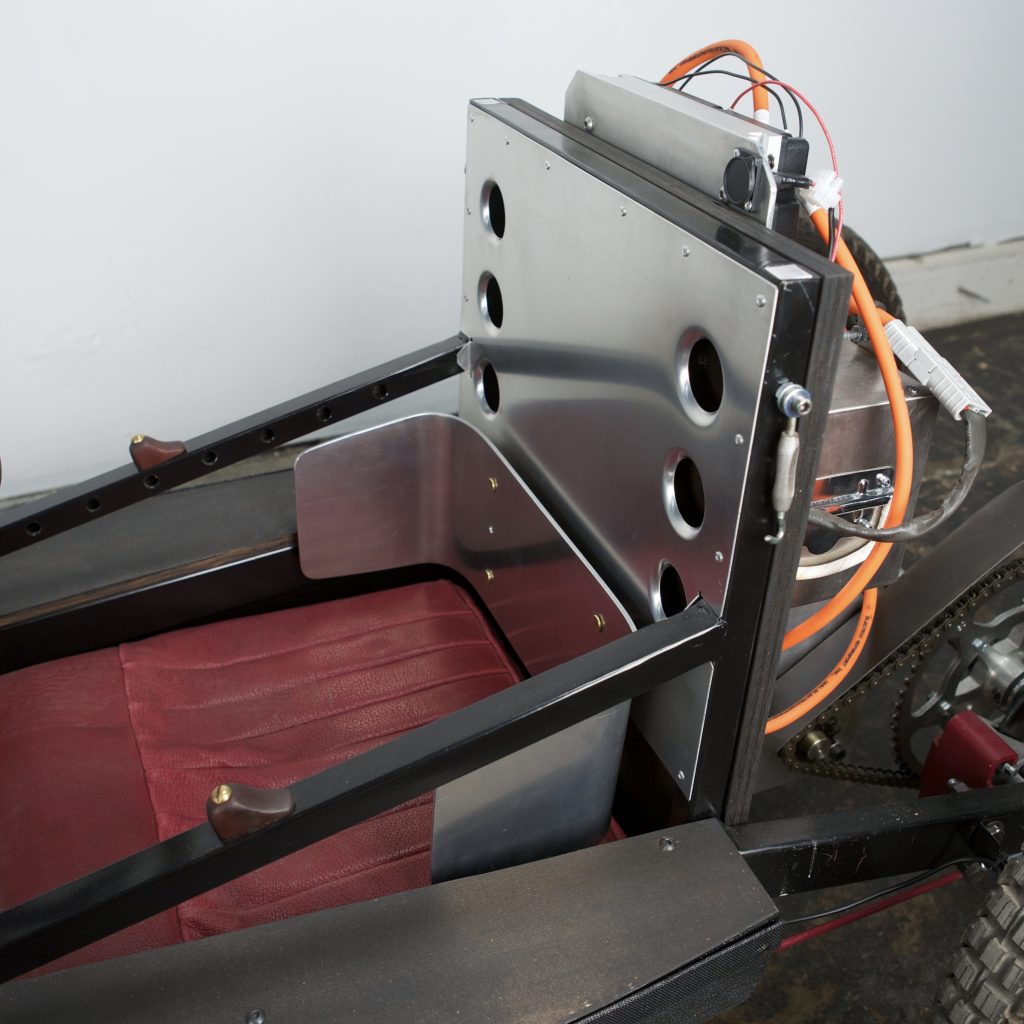

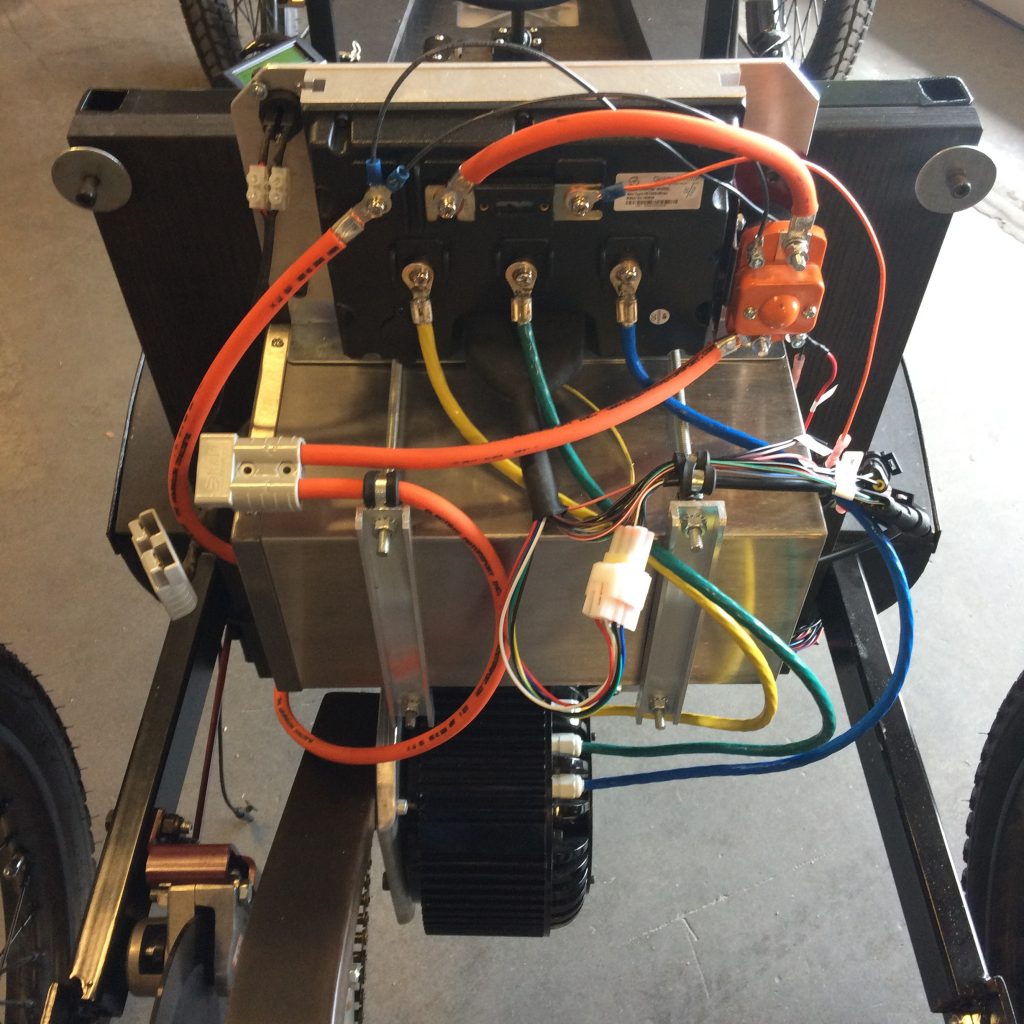

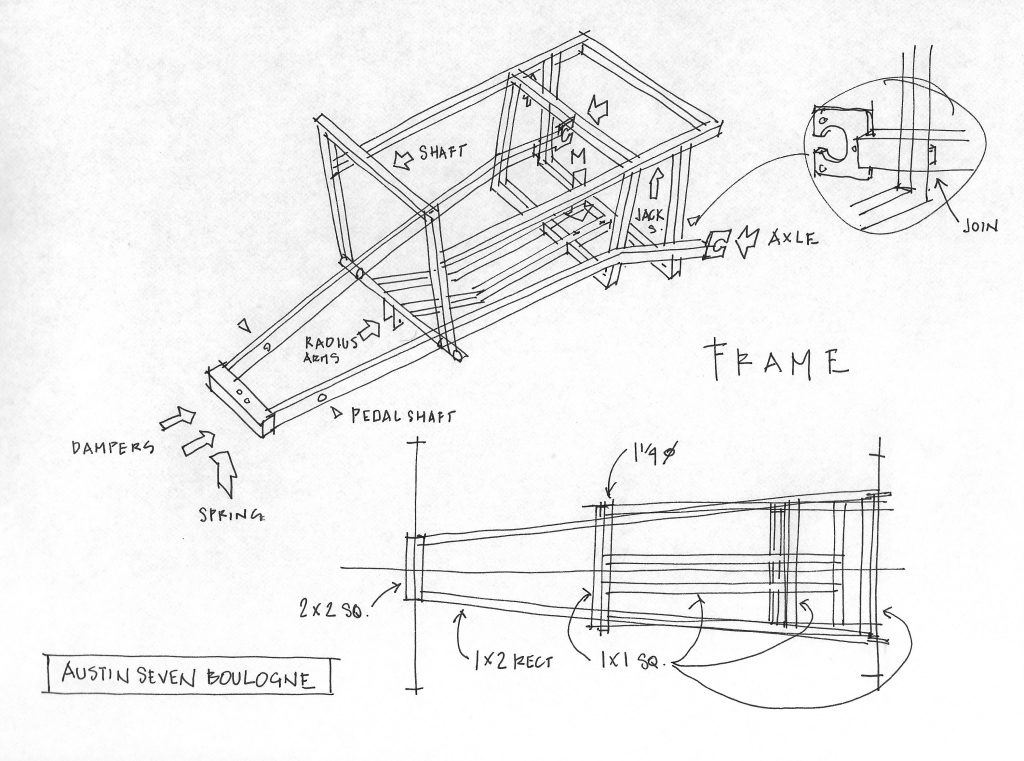

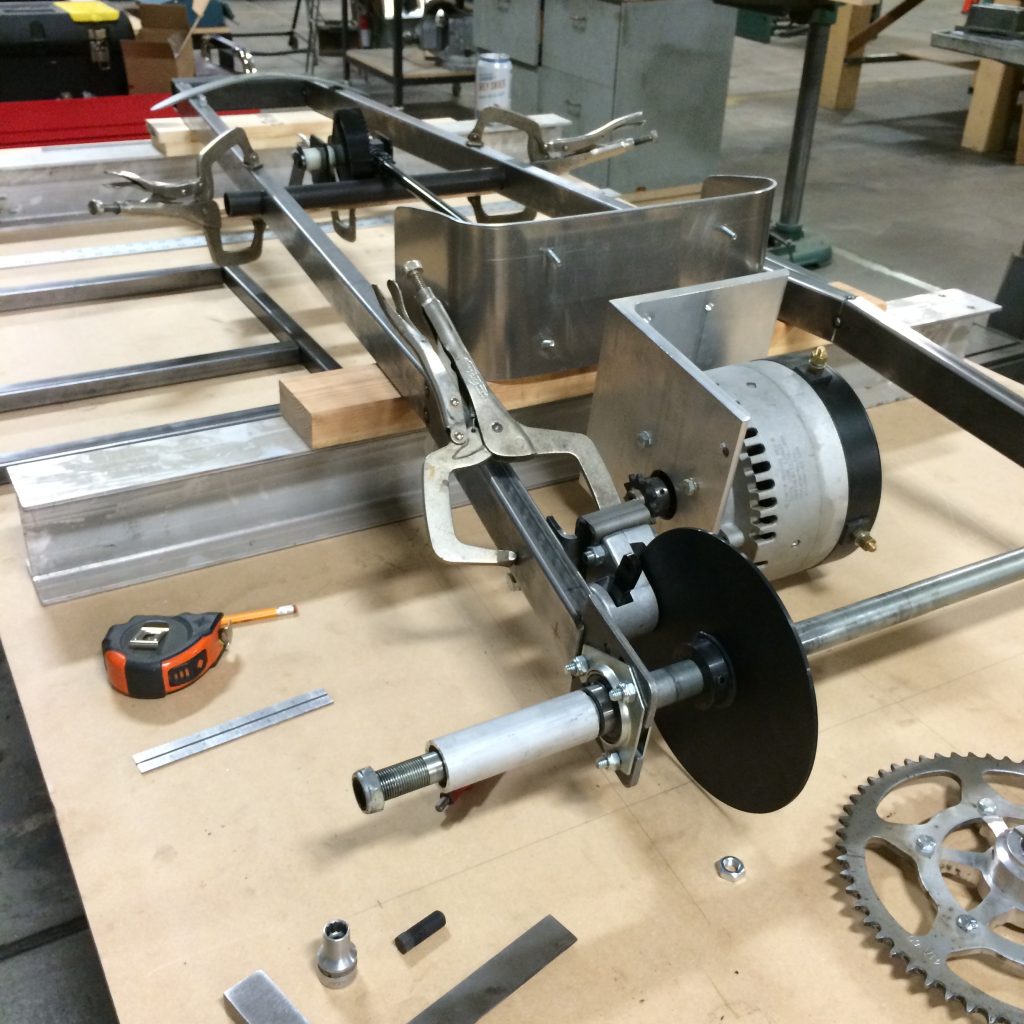

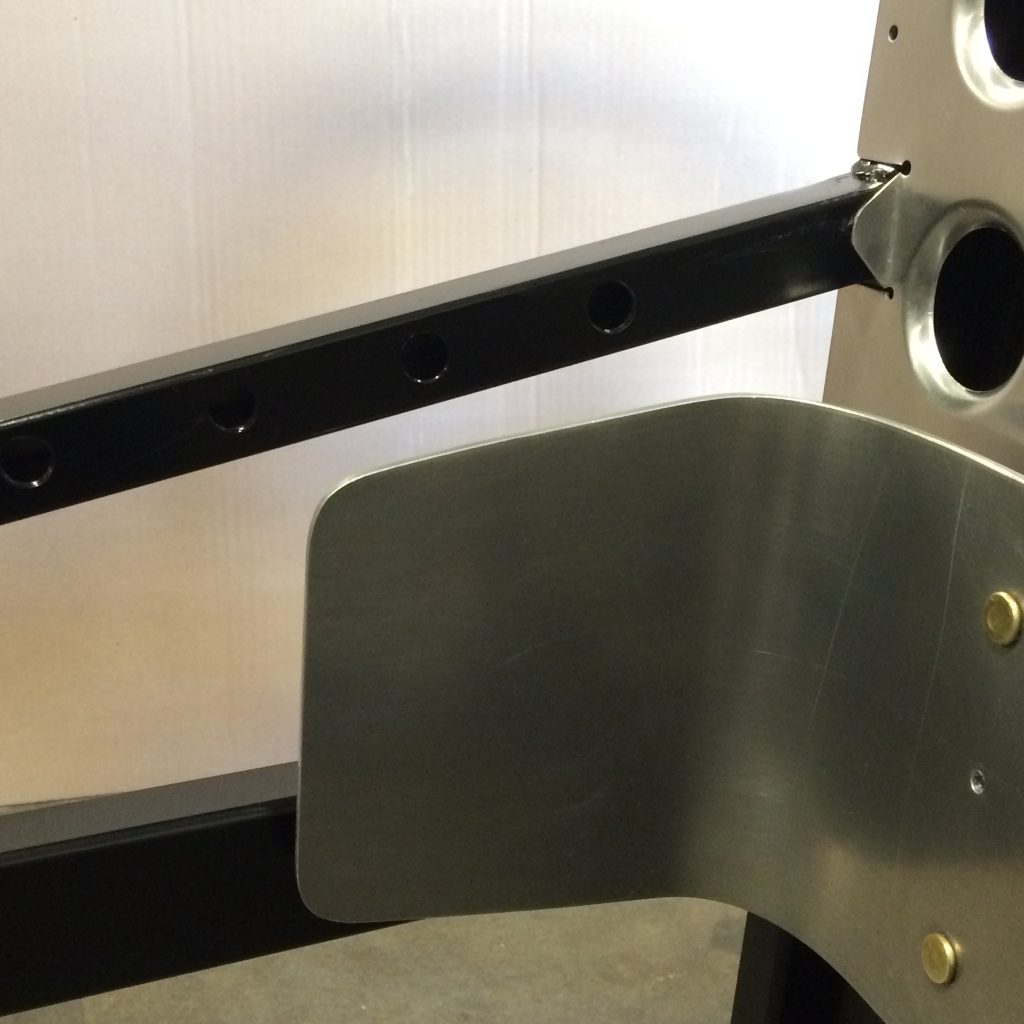

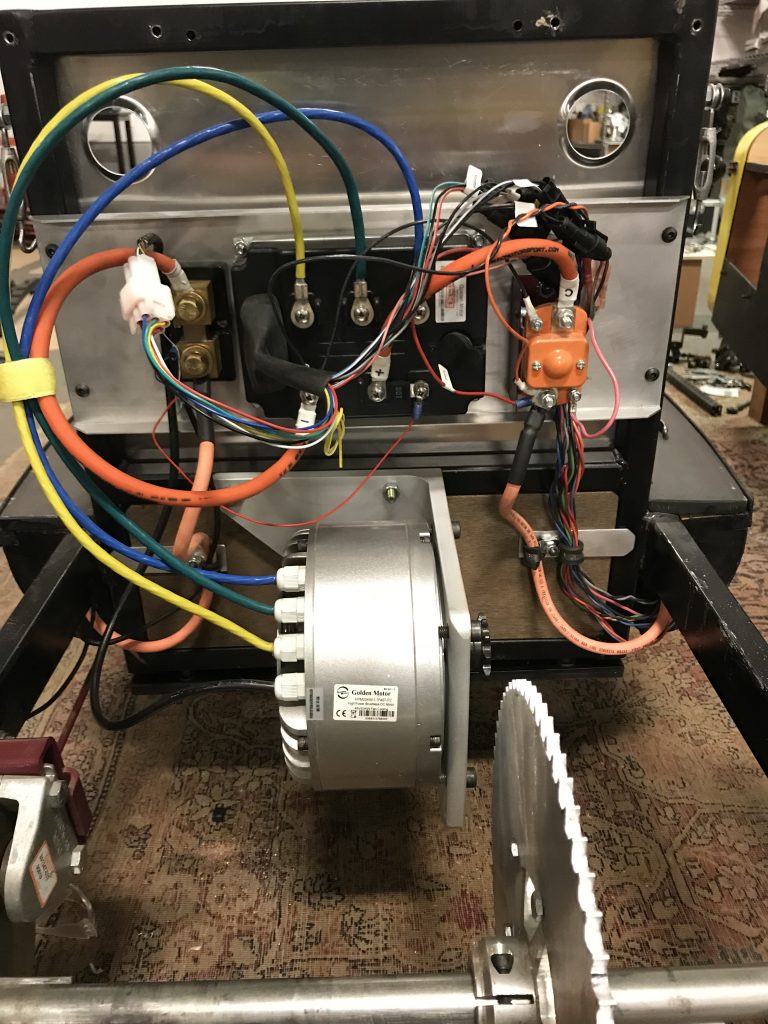

The project was begun with gas power in mind, the chassis was sketched as such and materials procured. This will help explain the structure around the driver which doubled as a crash structure (keeping in mind the intended fabric body) and was to magically hang the motor just in front of the rear axle with a jack shaft above it. That wonderful open space under the tail was a sacred cow for me. I had been mentor on the Morgan Green Build project and inspired by those forward thinking youngsters, had converted my Bugatti to electric. As welding began on the Austin frame the decision was abruptly made to go electric. The initial drive package would be pilfered from the Bugatti.

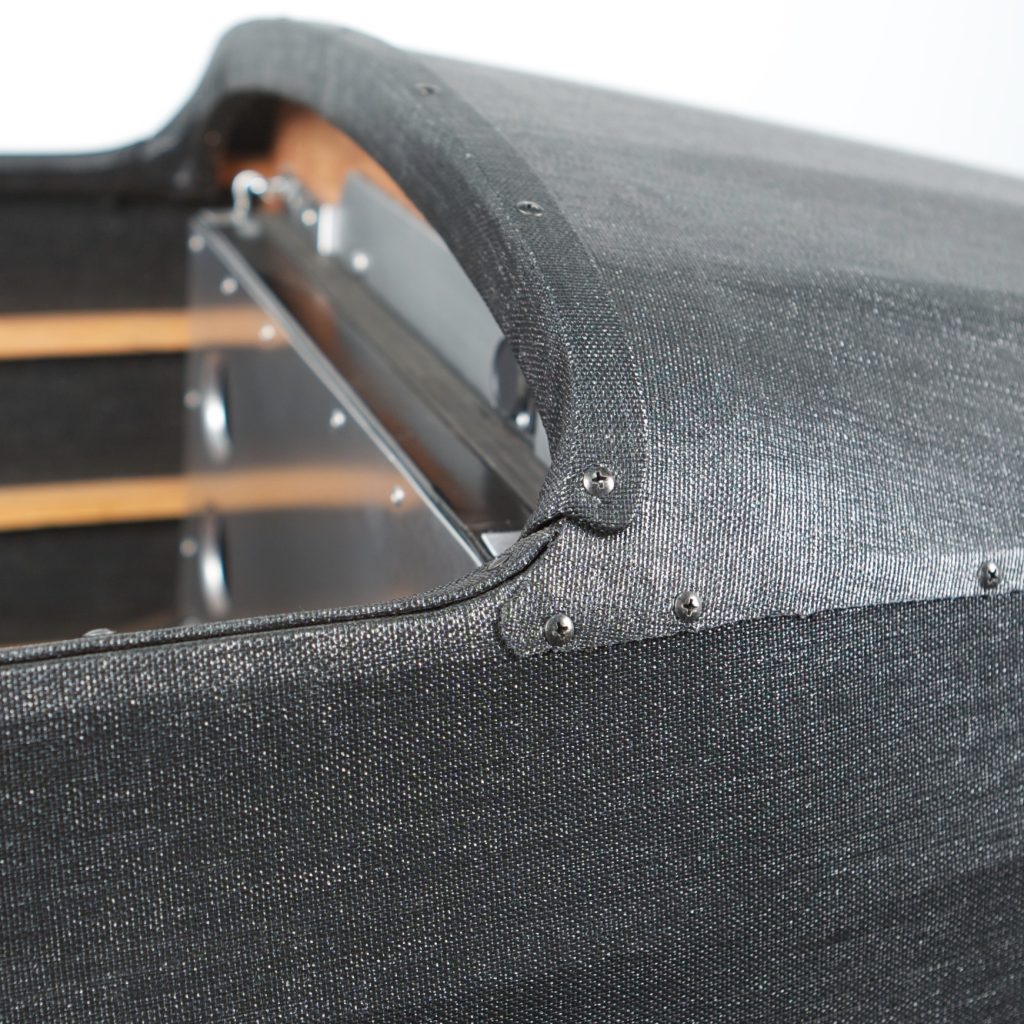

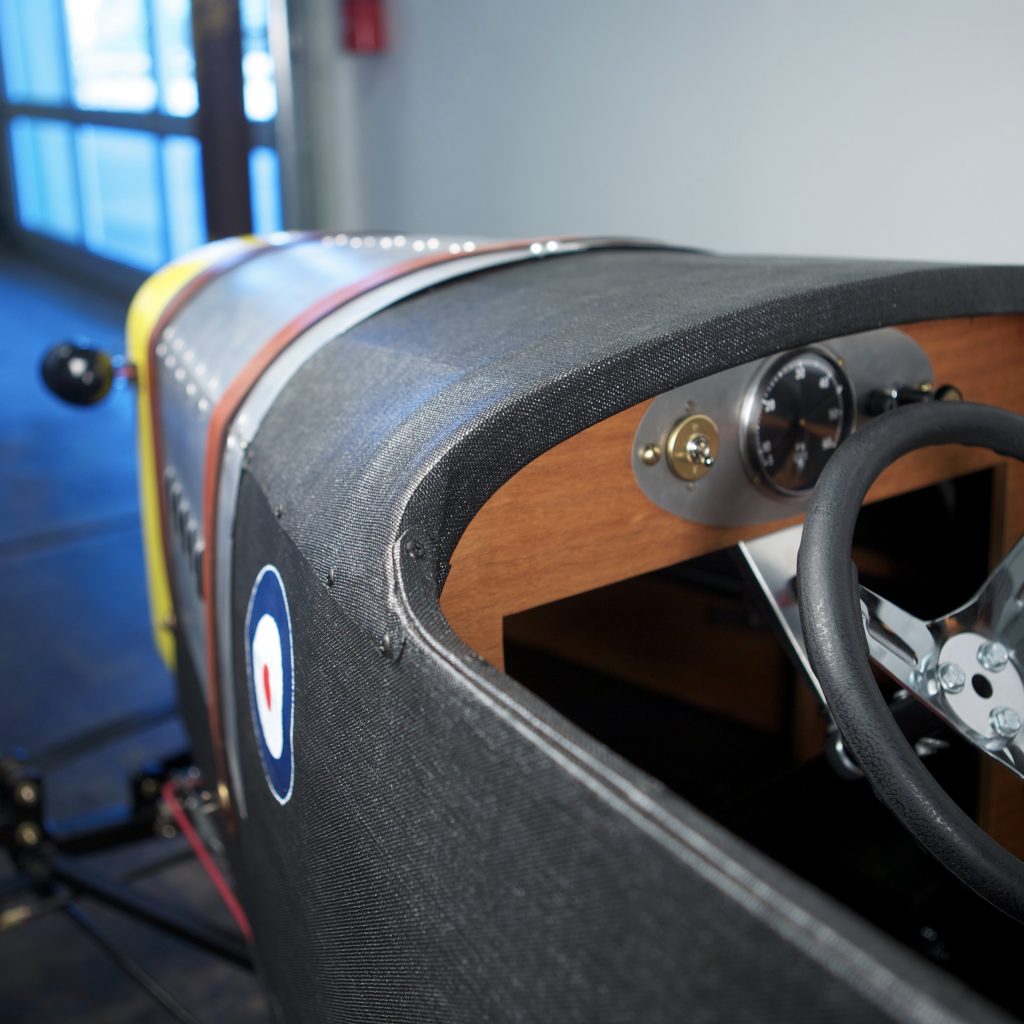

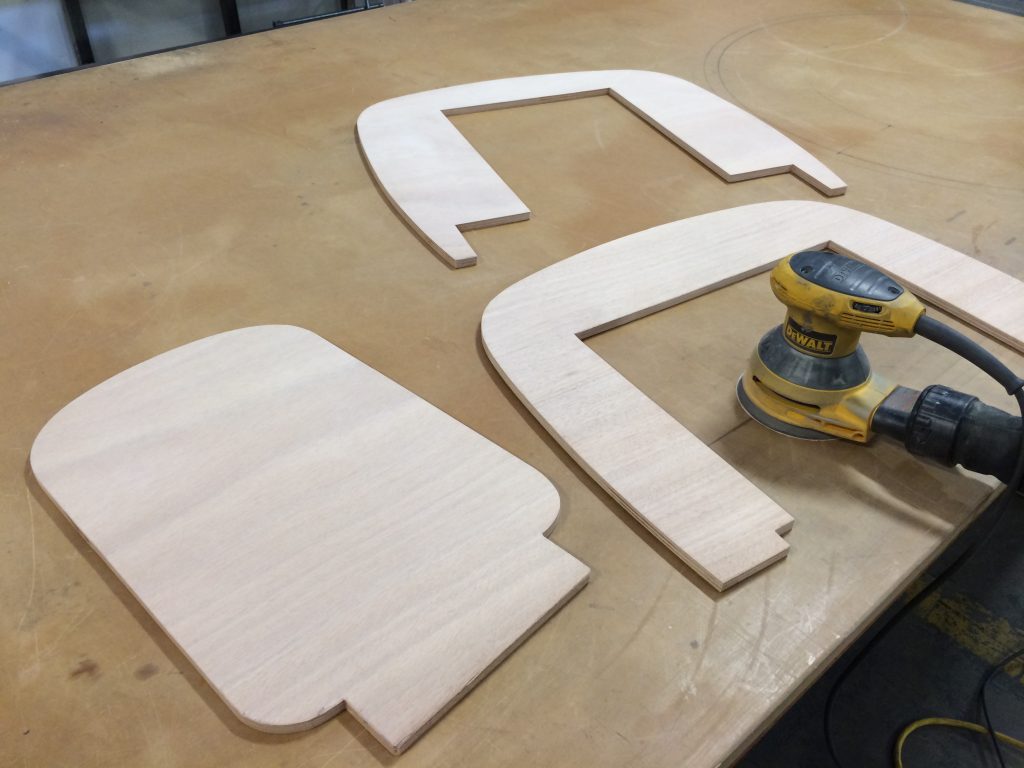

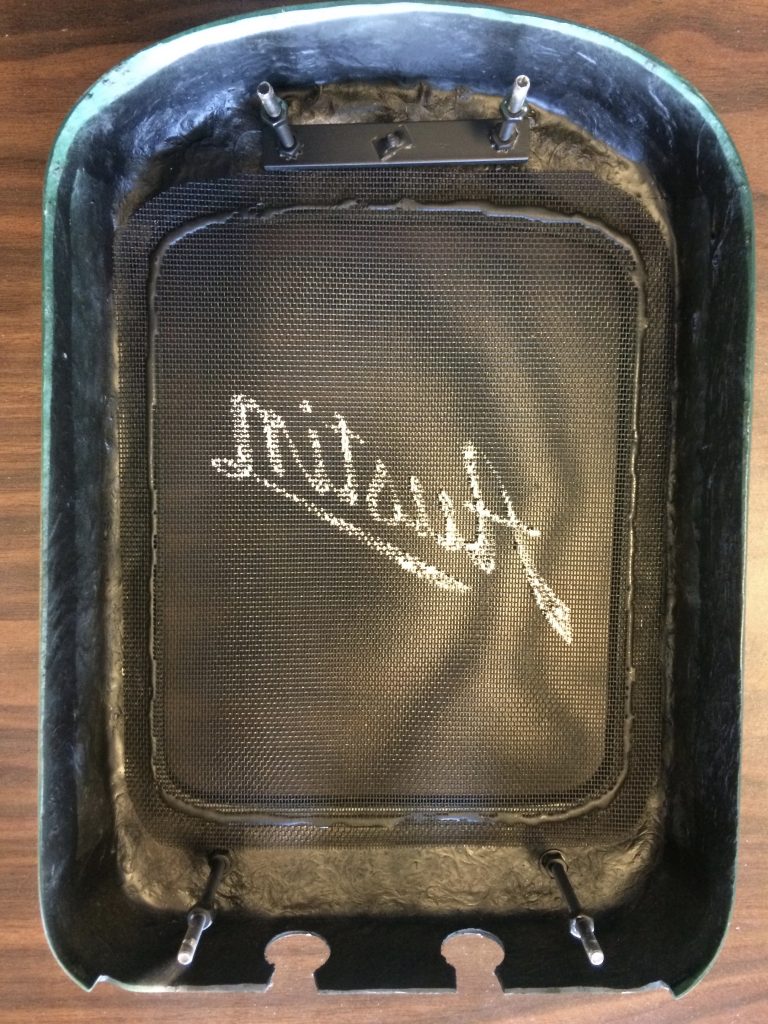

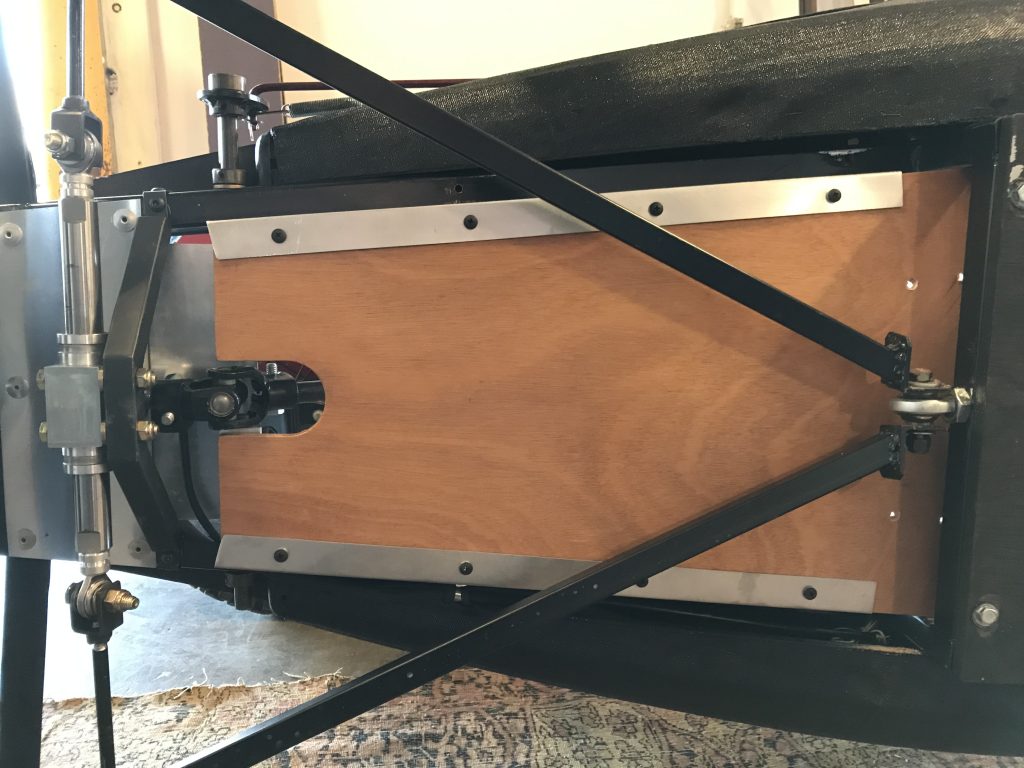

There were two main thrusts to the Austin Seven Boulogne project. Electric was a wonderful, fresh challenge to try to master and construction of the fabric body was an intriguing puzzle to work out. Just how light could this be? It was decided to push it farther than just stretching fabric over a stout frame and edge it toward making it almost nothing but fabric. Three lightweight marine plywood bulkheads are strung together with marine ply and clear fir strips then shrink wrapped in fabric. As a secondary learning experience I also wanted to try my hand at fiberglas and executed the radiator shroud that way. I foolishly listened to well meaning advice from the boat shop where I bought the mat and resin. I made the radiator much more robust than it needed to be. Still, the complete body with bulkheads and radiator shell is 23lbs. The radiator is a disproportionate chunk of that! What would Colin Chapman say?

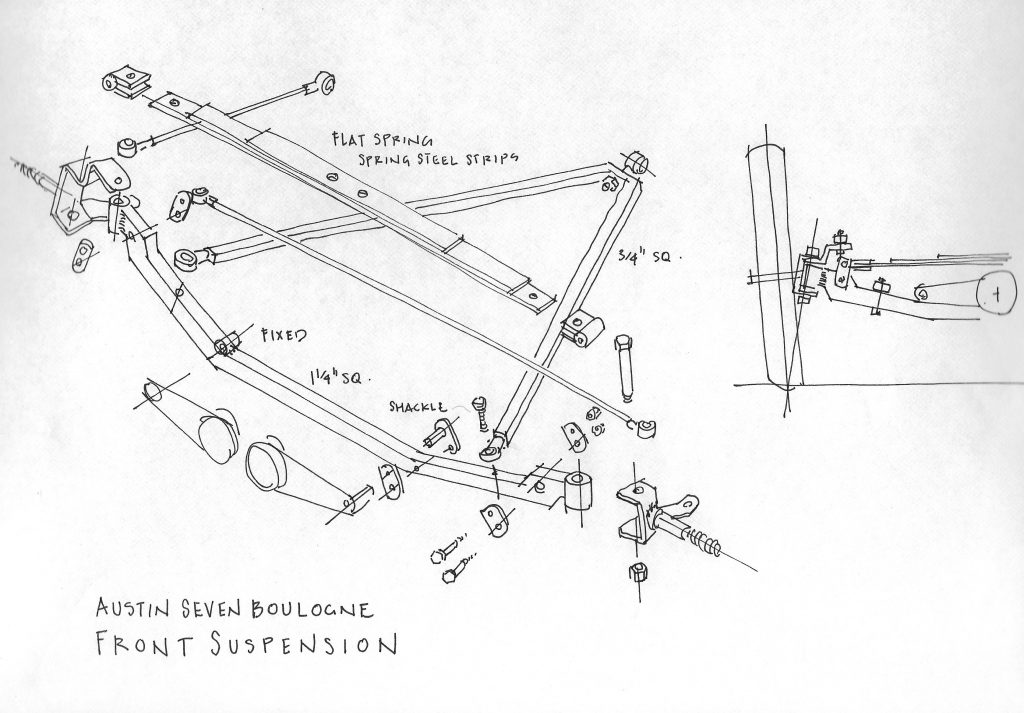

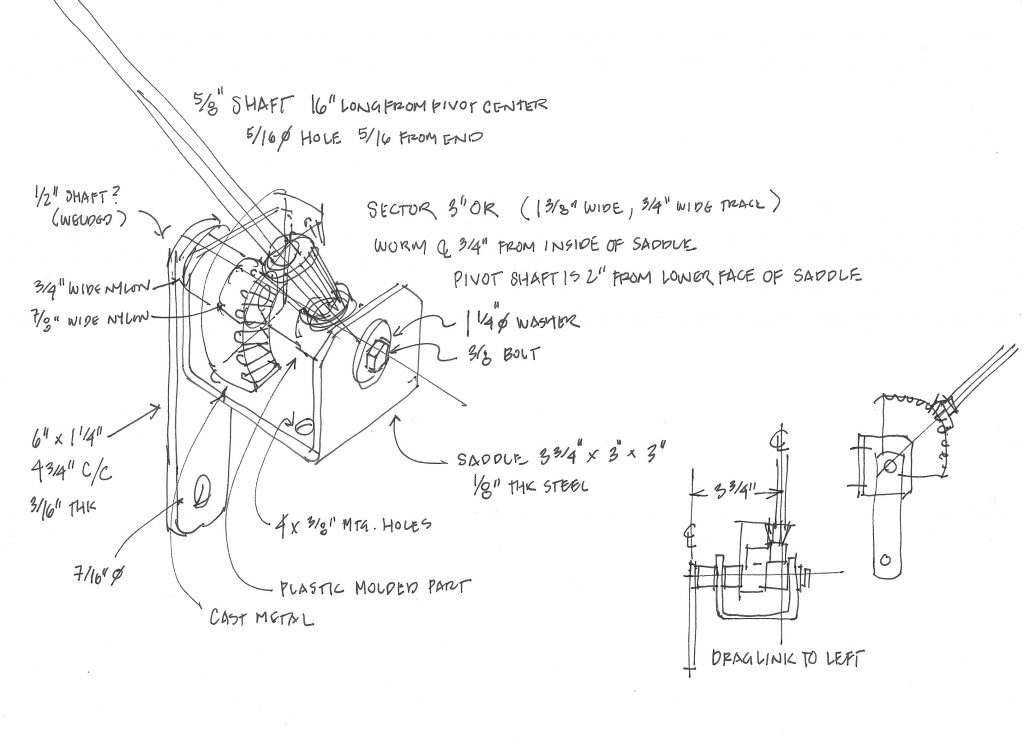

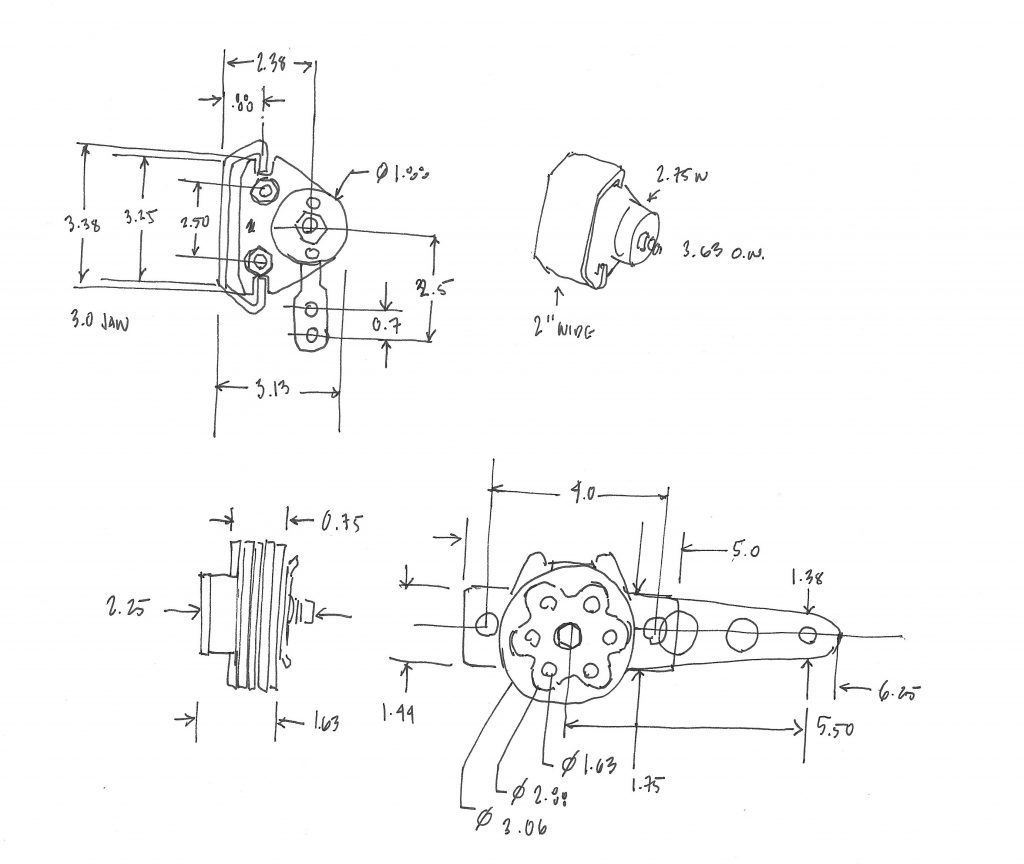

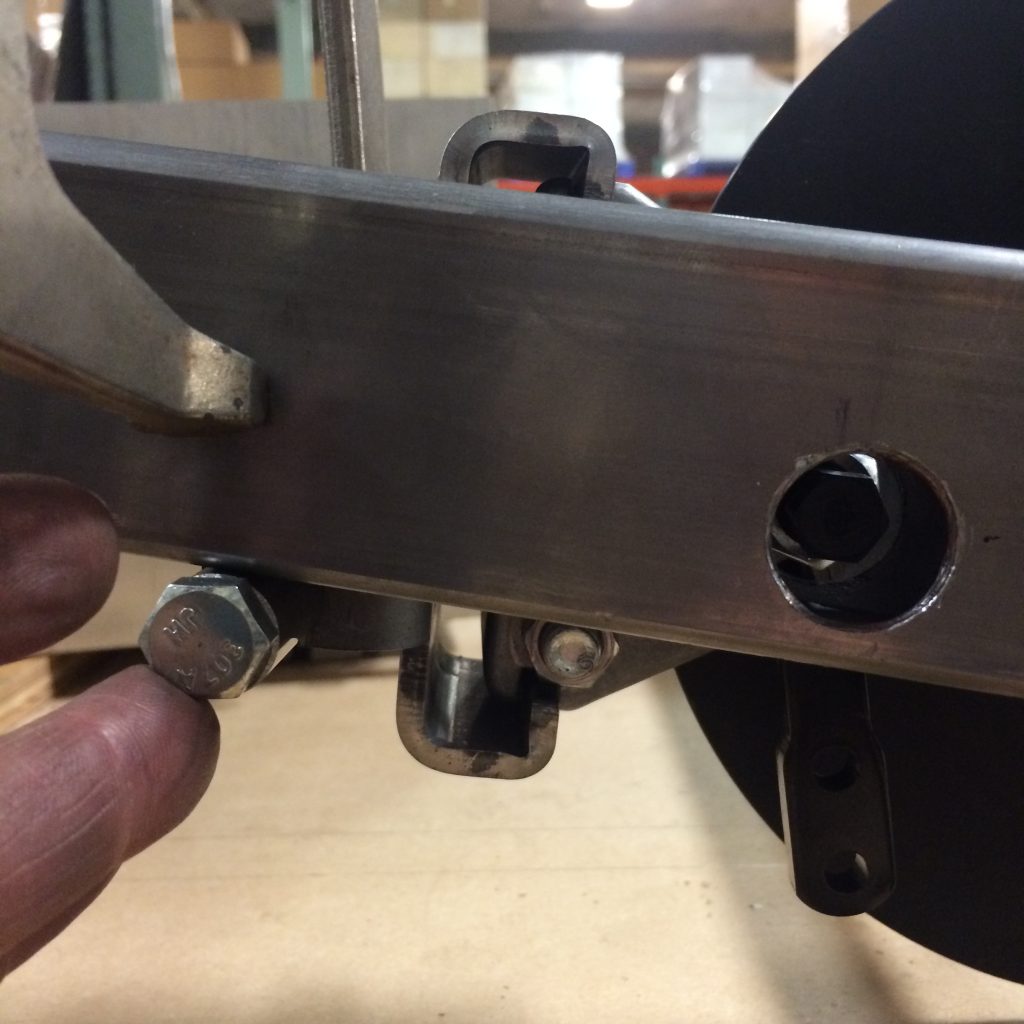

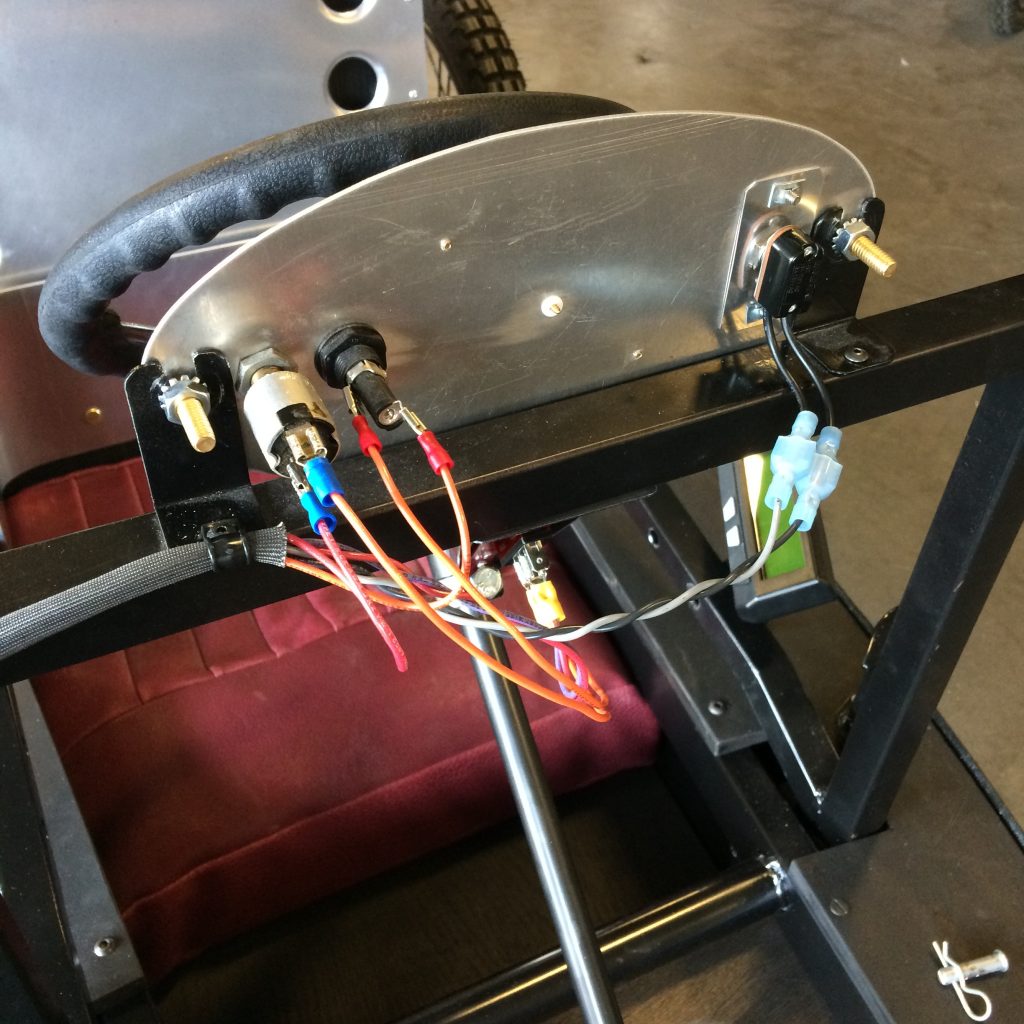

I wanted to emulate the famous Austin front suspension as closely as I could with its big A-arm and drag link steering. The front axle is a dressed up version of what I had come up with previously on my Peugeot. Lord Austin’s Seven was heavily inspired by the earlier Quadrilette so this seemed more than appropriate. I started with an inexpensive worm§or steering box from a riding lawn mower. I am not a fan of heavy caster so this wandered a bit. A proper Angle Gear was found on Amazon for less than the cheap mower part (it had been returned and lacked a box and instructions… I didn’t need the box or instructions). Installing this made the car delightful to drive. Eventually though, the car was converted to rack&pinion in order to be able to re-angle the steering column and create space for a new, more energy dense battery under the drivers legs; an effort to improve balance and reduce weight.

The Austin garnered some significant press on the strength of my good friend Guy Gadbois’ glamour photography. It was published in several technology and design publications including WIRED.

GUY GADBOIS GALLERY

TECHNICAL DESCRIPTION

Chassis No.: 1409

The Austin Boulogne build was started late in 2014 and duly completed in time for Tieton III (2015). The car was then heavily revised in 2016 with a new drive/battery package and improved steering. Subsequently, the drive package was changed yet again and the front axle upgraded. Reflecting all that, specifications are organized in three columns below. The gallery above shows the middle (2016) version of the car.

2015

2016

Current specification

Motor: Motenergy ME0708 PMDC.

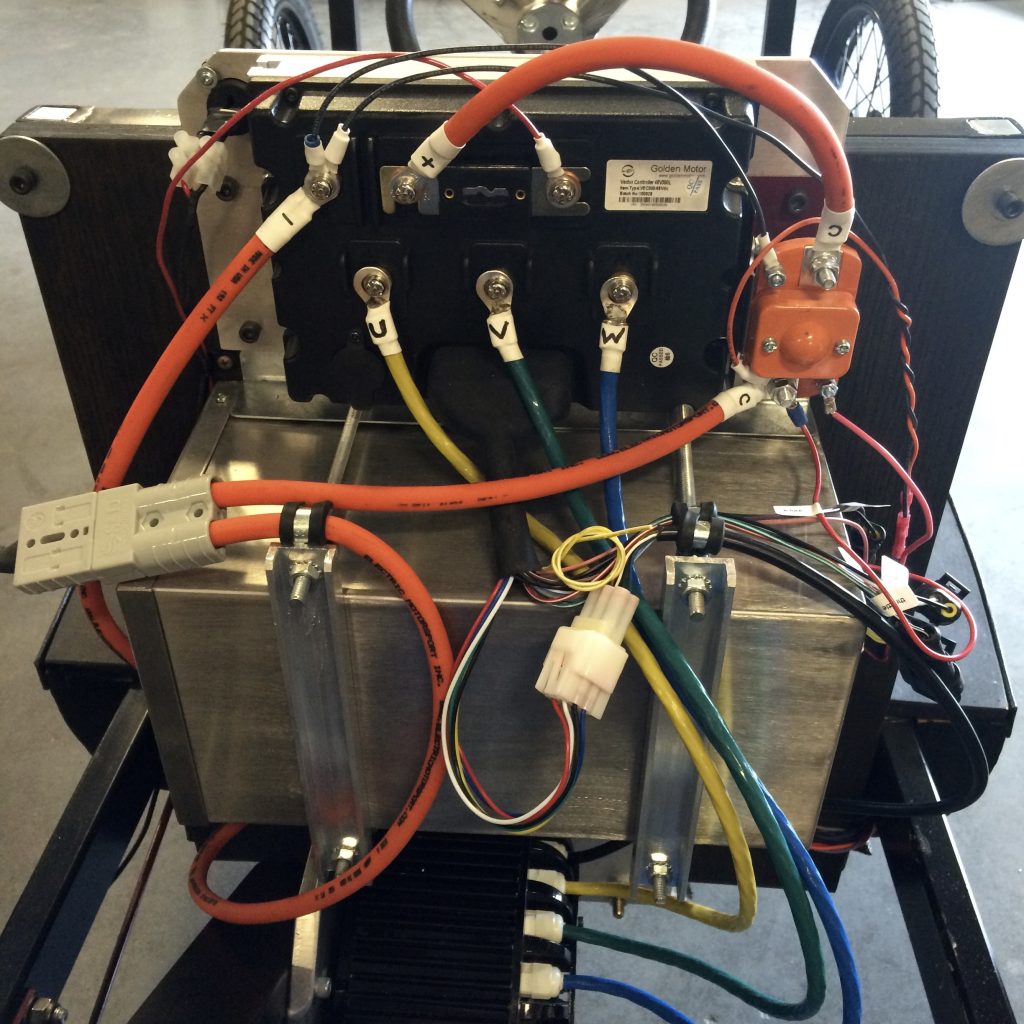

Goldenmotor 5KW BLDC

Goldenmotor 3KW BLDC

You can see the trend, less and less (paper) power because the batteries are out of sync and can’t possibly support the motors’ potential. Gittreville has a hard cap at 48V (nominal) for safety reasons. All these motors are designed to run at up to 72V (nominal). Simply put, higher voltage spins the motor faster which translates into higher power.

48 Volts (nominal) is internationally recognized as the prudent limit for human shock risk. Our skin is a decent insulator (barrier to shock) but what is under our skin is a tremendous conductor. CK accidents can easily break the skin.

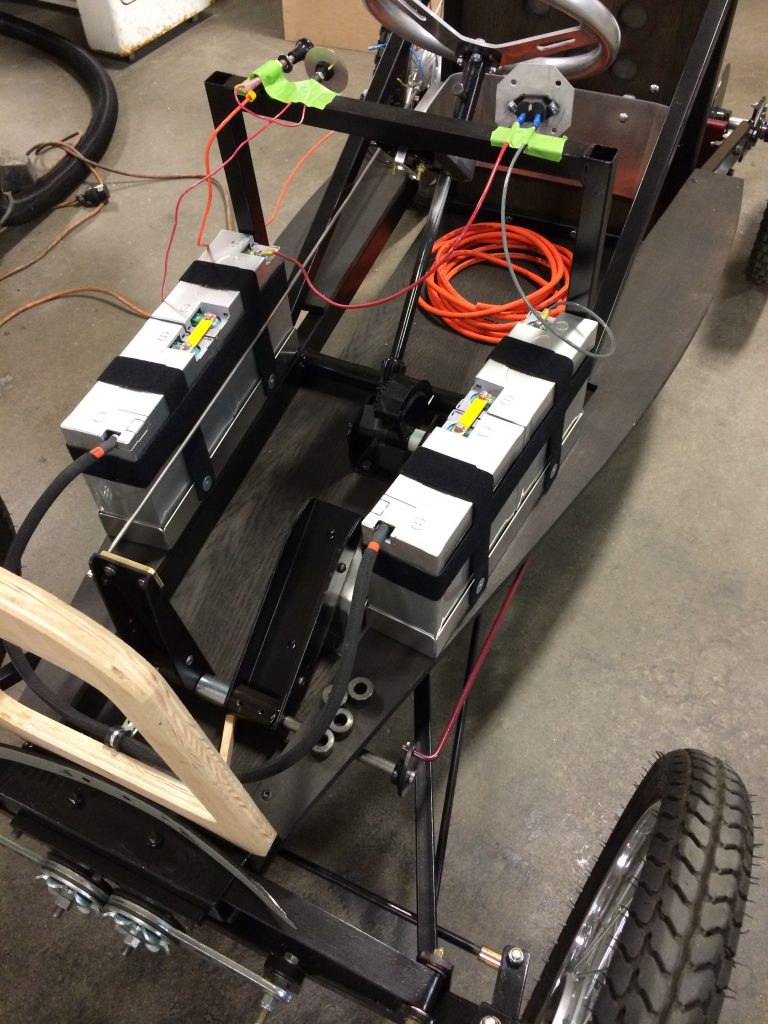

Batteries: 4x 12V LiFe packs with cell balancers in series.

Changed to 48V LiFePO4 20AH battery pack with integrated BMS.

AllCell 48V “Naked” Li-ion 23AH pack.

Combined weight of motor and batteries dropped precipitously with each of these changes. The car shed ~30lbs from Mark I to Mark III. If there is a next step for the Austin it will be to try two 48V packs on a bus to better support the motor.

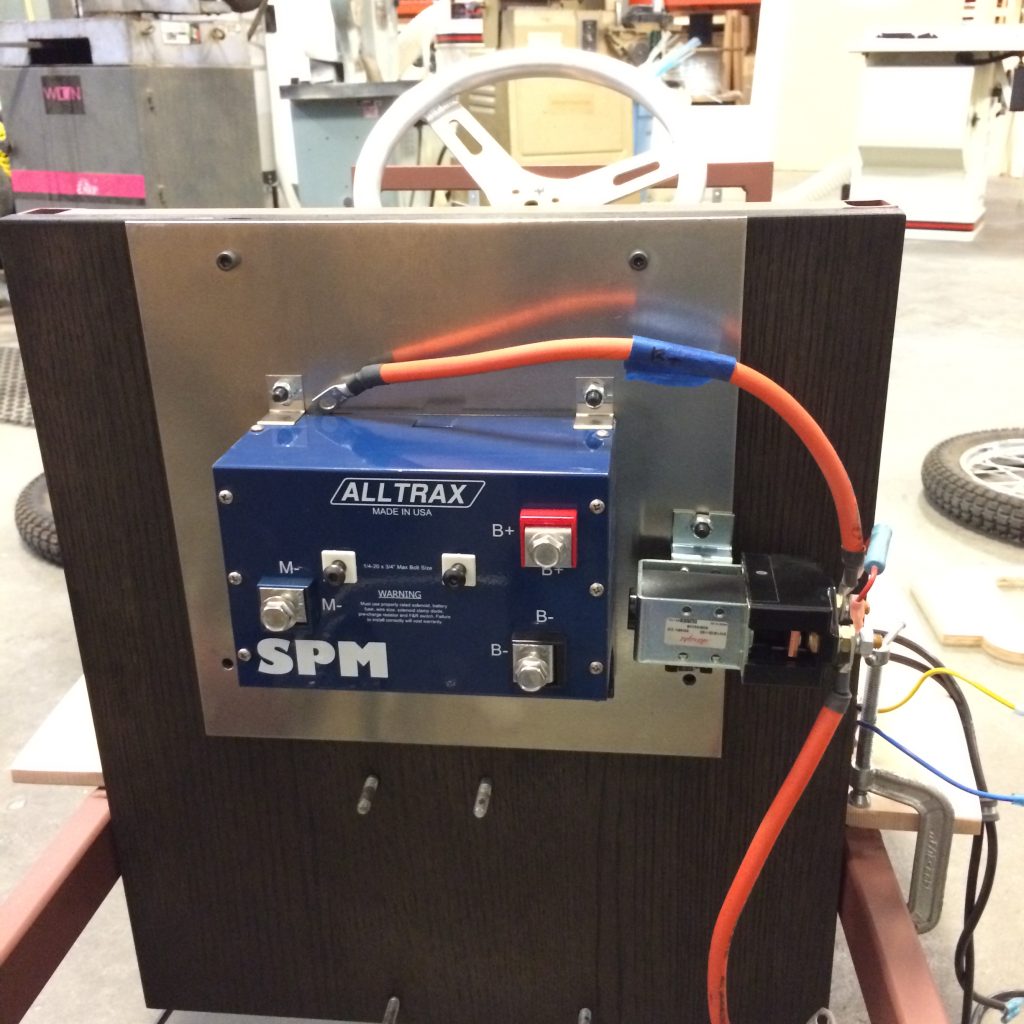

Controller: Alltrax SPM with PMDC motor.

200A Sine Wave controllers with both BLDC motors.

NB: 200A is a nonsense standardized rating, in reality 80A.

Transmission: None, #41 chain. Ratios have varied. Presently 10T drive x 72T driven

Brake: 8″ mechanical disk on left side of rear axle, controlled by foot.

Wheels: Vietnamese Honda type clones (steel rims). 17×140. Front wheels used in front. Rear wheels used in rear with Minihub type sandwich mounting.

Tires: 2.50 Michelin “Gazelles” front/2.50 Cheng Shin “trials” rear.

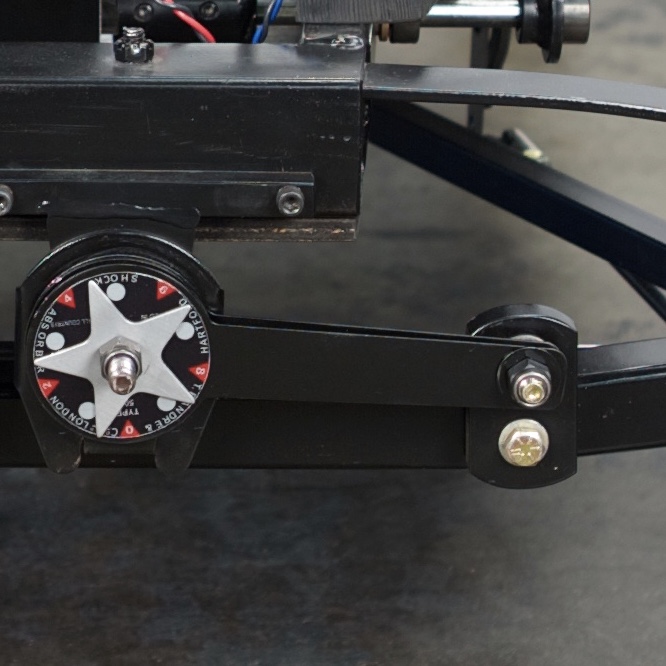

Front suspension: Transverse leaf. Pair of Speedway T-Bucket friction dampers. Home brew spindle sets. Axle is 1.25″ sq.

Dampers replaced with André Hartford scaled down reproductions produced by Reginald Splitpin.

Spindles upgraded to a set with with king-pin bearings. Metric stub axles.

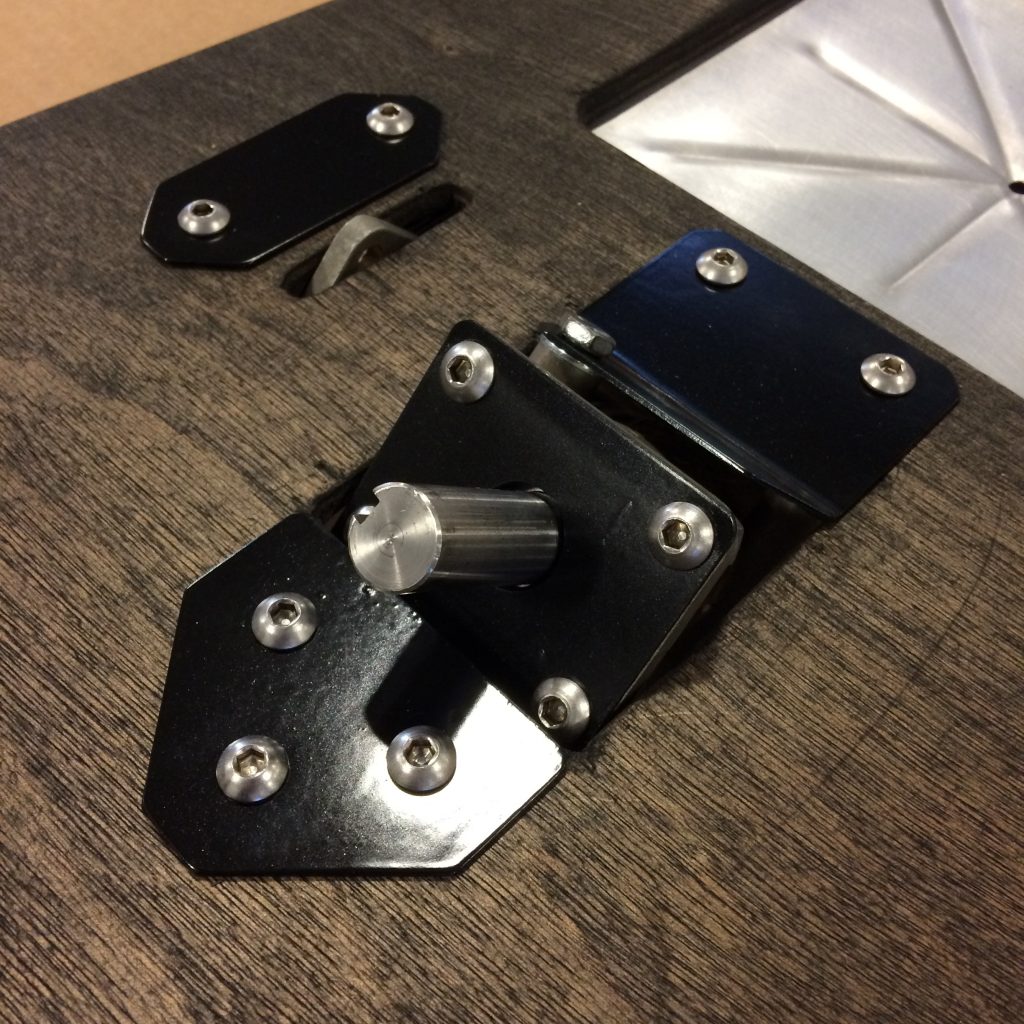

Steering: Worm&Sector from a riding lawn mower. Imprecise and a little disconcerting to have the exposed sector between one’s legs.

Steering box changed to an Angle Gear (and relocated). Handled delightfully.

Rack&Pinion (in conjunction with new spindles). Rack&Pinion allowed the steering shaft to pass over the new battery location.

Rear suspension: Rigid. The frame was fabricated to suggest the inspiration car’s trailing quarter elliptic springs.

Drive: Live axle/one wheel drive (a choice, although one wheel is never chosen).

Frame: Steel. Main members are 1″ x 2″ 0.125″ wall. Smaller members are 1″ sq. 2″ sq. at nose (spring carrier) and Ø 1 1/4″

Bodywork: Mostly fabric on wood framework (think early aircraft construction). Marine plywood bulkheads, plywood and clear fir stringers. Xorel fabric covering. Fabric is not painted. Aluminum bonnet. Fiberglas radiator shell.

DIMENSIONS

Wheelbase: 65 1/2”

Ground clearance: 7”

Front track: 36 1/2”

Rear track: 33”

Overall length: 93”

Body width: 26”

Height: 33”

Radiator width: 11 3/4″

Weight: 246 lbs

BUILD GALLERY

by Johnny Dumfries

Well, what can you say?

Beautiful!

Wow. What a lovely little machine this is. Superb!